Key Takeaways: This article will shed light on core details of 17-4PH material, including composition, physical properties, mechanical properties, H900 and H1150 conditions, and comparisons with 304 and 316L stainless steel.

Are you looking for a high-strength stainless steel that can handle extreme environments, such as aerospace engine components or oilfield valves? Look no further than 17-4PH. It outperforms common stainless steel like 304 and 316L because of its customizable hardness, excellent machinability and corrosion resistance.

But what exactly is 17-4PH? What are its key properties, heat treatment conditions (like H900 and H1150), and equivalent grades? This guide answers all these questions and more, with data-driven comparisons and practical tips to help engineers, buyers, and manufacturers select the right material for their projects.

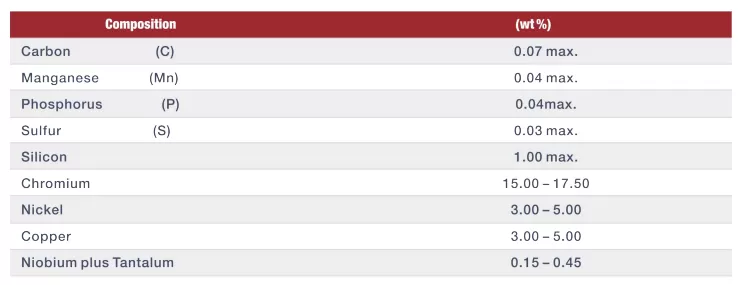

17-4PH is a precipitation-hardening martensitic stainless steel designed for high-strength, corrosion-resistant applications. It achieves customizable mechanical properties through a two-step heat treatment process, making it one of the most versatile specialty stainless steels in industrial manufacturing.

| Property | Value |

|---|---|

| Density | 7.80 g/cm³ |

| Melting Point | 1400–1440°C (2550–2620°F) |

| Thermal Conductivity | 19.8 W/m·K (20°C) |

| Coefficient of Thermal Expansion | 10.8 × 10⁻⁶ /°C (20–100°C) |

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|

| Annealed (Condition A) | 860 | 725 | 10 | 28–32 |

| H900 | 1310 | 1170 | 7 | 40–44 |

| H1025 | 1170 | 1035 | 9 | 35–39 |

| H1100 | 1000 | 860 | 12 | 31–35 |

| H1150 | 930 | 725 | 14 | 28–32 |

| H1150M | 860 | 725 | 16 | 26–30 |

17-4PH's mechanical properties are fully customizable via solution treatment and aging (precipitation hardening). The following are the most searched-for conditions:

| Condition | Aging Temp (°F) | Aging Time (hrs) | Best For |

|---|---|---|---|

| H1025 | 1025 | 4 | Balanced strength/toughness |

| H1100 | 1100 | 4 | Stress relief & stability |

| H1150M | 1150 | 2 | Overaged for maximum ductility |

| Application Priority | Recommended Condition |

|---|---|

| Maximum strength/hardness | H900 |

| Balanced strength/toughness | H1025 |

| Maximum toughness/ductility | H1150 / H1150M |

| Thermal stability/stress relief | H1100 |

After understanding 17-4PH's composition, properties and heat treatment conditions, the next critical step for engineers and buyers is to select the right stainless steel grade for specific applications. 17-4PH, 304, 316L, and 410 are all mainstream options, but they differ significantly in strength, corrosion resistance, cost, and usability.

To help you make informed decisions, below is a comprehensive comparison of their core performance metrics, followed by targeted guidance on which grade to choose in different scenarios.

|

Comparison Metric |

17-4PH (UNS S17400) |

304 (UNS S30400) |

316L (UNS S31603) |

410 (UNS S41000) |

|---|---|---|---|---|

|

Steel Type |

Precipitation-Hardening Martensitic |

Austenitic |

Austenitic (Low Carbon) |

Martensitic |

|

Tensile Strength (MPa, Annealed) |

860 (Up to 1310 after heat treatment) |

620 | 620 |

485 (Up to 1030 after heat treatment) |

|

Hardness (HRC, Typical) |

28-44 (Adjustable via heat treatment) |

20-25 | 20-25 |

20-45 (Adjustable via heat treatment) |

|

Corrosion Resistance |

Very Good (Comparable to 304; resists atmospheric/neutral salt corrosion) |

Excellent (General corrosion resistance; poor in chloride environments) |

Best (Superior to 304; resistant to marine/chloride/chemical corrosion) |

Good (Basic corrosion resistance; inferior to others in harsh environments) |

|

Magnetic |

Yes | No | No | Yes |

|

Heat Treatability |

Yes (Precipitation hardening; customizable strength/hardness) |

No (Cannot be hardened via heat treatment) |

No (Cannot be hardened via heat treatment) |

Yes (Martensitic hardening; limited toughness after hardening) |

|

Machinability |

Good (Best in annealed state) |

Fair (Requires proper tooling/coolant) |

Fair (Slightly worse than 304 due to higher alloy content) |

Good (Better than austenitic grades) |

Based on the above comparison, here's a practical selection guide to match grades with application needs:

Choose 17-4PH: When you need high strength + corrosion resistance + customizable hardness. Ideal for aerospace components (fasteners, turbine blades), oil & gas valves, medical implants, and high-load industrial parts. Recommended heat treatment conditions: H900 for maximum strength, H1150 for maximum toughness.

Choose 304: For general-purpose, cost-effective applications with basic corrosion resistance. Suitable for food processing equipment, household appliances, architectural fixtures, and non-harsh industrial environments where high strength is not required.

Choose 316L: When corrosion resistance (especially in chloride/marine environments) is the top priority. Perfect for marine hardware, chemical processing equipment, coastal architectural parts, and medical devices that require high biocompatibility and corrosion resistance.

Choose 410: For low-cost, basic corrosion-resistant applications that need moderate hardness. Suitable for simple mechanical parts, valves, pumps, and tools in dry or slightly corrosive environments. Not recommended for marine or chemical harsh conditions.

To sum up, 17-4PH stainless steel (UNS S17400, EN 1.4542) is a standout choice for high-strength, corrosion-resistant applications, filling the gap that 304, 316L, and 410 can't cover. Whether you need H900 for maximum hardness, H1150 for toughness, or a grade compliant with ASTM A564/AMS 5643 standards, 17-4PH adapts to your project needs.

If you're ready to source premium 17-4PH material or need personalized technical advice, contact our team for a free quote today.

25th floor, C3 Building, Wanda Plaza, Kaifu District, Changsha, Hunan Province, China